Craftsmanship

An introduction to the process of Jewellery Card manufacturing resembles a tour inside a huge oceanarium. A variety of processes and machines pass in front of your eyes like exotic fish. It is impossible not to think “this is immeasurably more interesting and beautiful than it seems”.

Using up-to-date technologies of 3D-modeling, precise casting and meticulous manual work makes it possible to craft jewellery of the highest quality matched to the best European brands. Cooperation with such companies as Swarovski and Signity - the biggest world suppliers of natural gemstones, complement a splendid bouquet of the exclusive collection of High Jewellery with the pureness of exquisite diamonds and rich tints of topazes and sapphires.

-

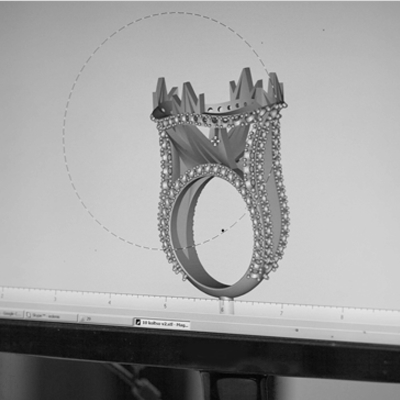

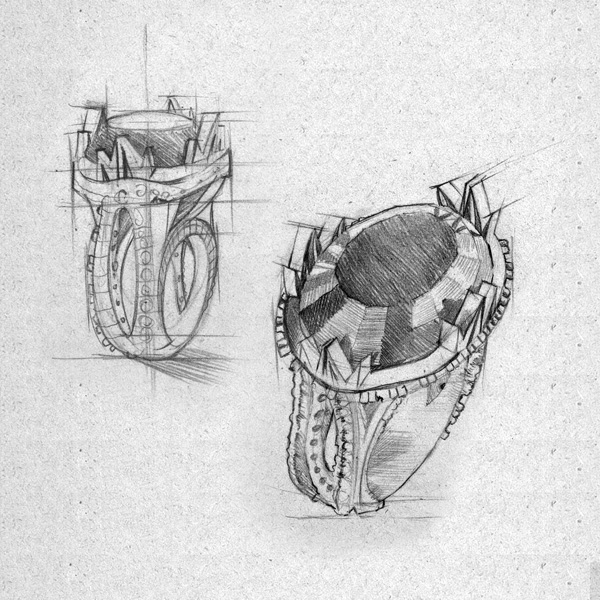

Sketch, 3D-modeling

The future piece of jewellery being born on paper. Its sketch is created by leading artists of Jewellery Card. When it is completed, 3D-designers are brought into. They carefully transfer the design from the sketches into digital models, which are still intangible but you already want to try it on.

-

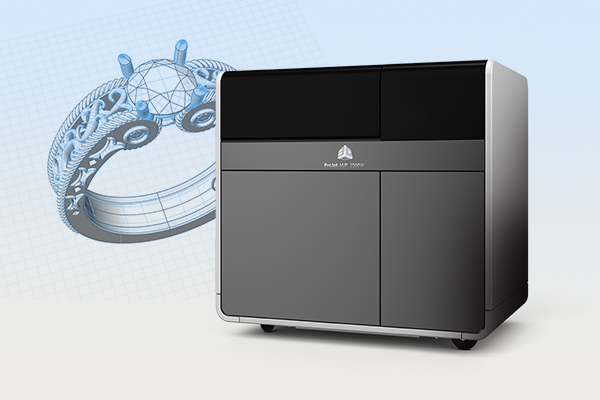

3D-printing, wax form creation

After a thorough development of all projections, digital rendering of future jewellery is sent for development into Envisiontec Perfactory Micro and 3D Systems ProJet MJP 2500W specialized 3D-printers. This allows our craftsmen to create exact features of the model designed by artists on paper. Afterwards, micron by micron with surgical precision, 3D-printer creates already tangible polymer items of future jewellery. Afterwards, before preparing forms for casting, masters of jewellery house start to assemble a “tree” - special polymer construction, into which all the items created on the 3D-printer are soldered.

-

«Tree» assembly, filling and casting

On the same “tree” can be placed items of same fineness and colour of gold. When the “tree” is ready, craftsmen cast it with special modelling mass in a complete vacuum in order to avoid a bubbles. It is then casted in a mass “tree” placed into the furnace in a special metal container called an opoka. After some time of heating, the modeling mass hardens and the wax “tree” evaporates completely. In its place an empty space is formed with the exact shape of the future pieces of jewellery. Into casted opoka, gold alloy of a necessary fineness is poured. But the precious metal still needs to be extracted at the gold refinery stage.

-

Refining and extracting of fineness gold

Our jewellery house uses a highly productive refinery complex of the Italian brand "B.T.T. ITALIA" for extracting “four nines” fine gold. That is how on professional slang sounds powder of purest gold which contains 99.99% of precious metal. Despite the complexity of the chemical process, within one day goldsmiths receive the necessary amount of purest precious metal from the raw materials containing gold. The highest fineness of gold is approved by the expertise of the inhouse certified production laboratory. It makes the cycle of the manufacturing process self-sufficient.

-

Preparation and melting of precious metal

It is a well-known fact that jewellery is not made of pure gold. Due to gold’s natural softness and vulnerability to physical damage, a piece of jewellery may easily be scratched or even lose its shape. That is why production uses a jewellery alloy of purest gold and “ligature” - compound of metals such as silver, copper, nickel, palladium, iridium, etc. Ready gold alloy is poured into the opoka, prepared at a previous stage.

-

Gold «tree», snapping and furnishing jewellery

At the moment of pouring into the opoka, alloy evenly fills every voided space left after evaporation of the wax “tree”. Once the opoka is cooled, jeweller washes it and exposes the “tree”, this time made out of gold. Afterwards the items are separated from the “tree” and passed to the next, but no less interesting stages such as mounting, affixing gems and polishing.

-

Mounting, gems affixing and polishing

At the stage of mounting, special attention is paid to every piece by Jewellery Card craftsmen, so the casted gold items still need to gain its glitter of final piece of jewellery, which our clients are used to. Thanks to the work of talented craftsmen at this stage, most of the jewellery from the High Jewellery collection is very intricate with a variety of parts united in a multi layered ensemble. Here every item takes its own place foreseen by the artist.

Affixing of gems is no less complicated, intensive and crucial process. All work on gems affixing is done by Jewellery Card craftsmen by hand. Not a single stone is glued. All of them are fastened by metal with highest accuracy under microscope.

At the stage of polishing, the jewellery acquires its magnifying glitter. Not even tiniest part on the outside or inside of every piece of jewellery is left without being polished. -

Control of quality and presentation of jewellery

The polished jewellery is thoroughly scrutinized by senior masters of Jewellery Card. Every piece of jewellery undergoes a thorough internal check. In case any faults are detected, a piece of jewellery is returned back to production stage. Only ideally crafted pieces of jewellery will receive company’s stamp.

According to ukrainian legislation, jewellery must be sent to Government Testing Office of Ministry of Finance of Ukraine. There the verification of gold fineness is carried out for every piece of jewellery crafted by our house.

Only after all these stages ready sets are delivered to our shops and showrooms to meet the clients of our jewellery house.